- Malaysia No. +60-1112874409

- India No. +91-9963 98 3699

- krish@globalindustrialsolutions.co

World Water Works inDENSE™ system increases process throughput and performance through the selection of dense sludge aggregates with improved settling rates and the promotion of enhanced biological phosphorus removal (EBPR).

inDENSE is a gravimetric selection technology that provides a method for retaining the denser biomass while wasting out the light fraction of the MLSS in the treatment system. Increased density can lead to improved settling characteristics, which allows for the prevention of biomass loss and subsequent treatment disruption, especially during wet weather scenarios.

Selection for faster settling particles, and process configuration and physical forces can encourage aerobic granular sludge. The hydrocyclones select dense granules through the underflow while the lighter solids are wasted via overflow. The use of an external selector for improving settleability and stabilizing EBPR, with or without the use of formal anaerobic selector, is a low capital cost investment for wastewater treatment plants.

BENEFITS

Achieves bio-P without process change

Allows for denser sludge selection

Solution for poor settling MLSS

Reduced and/or eliminated chemistry

Easily integrated into any existing plant

Rapid return on investment

Minimization of sludge loss

Operational stability

With conventional activated sludge (CAS) being the predominant wastewater treatment technology globally. One key requirement of this technology is the ability to effectively separate the liquid and solid fractions. Floating or bulking sludge, at least temporarily, has affected the treatment capacity and performance of many of these facilities. World Water Works' inDENSE technology solves this problem.

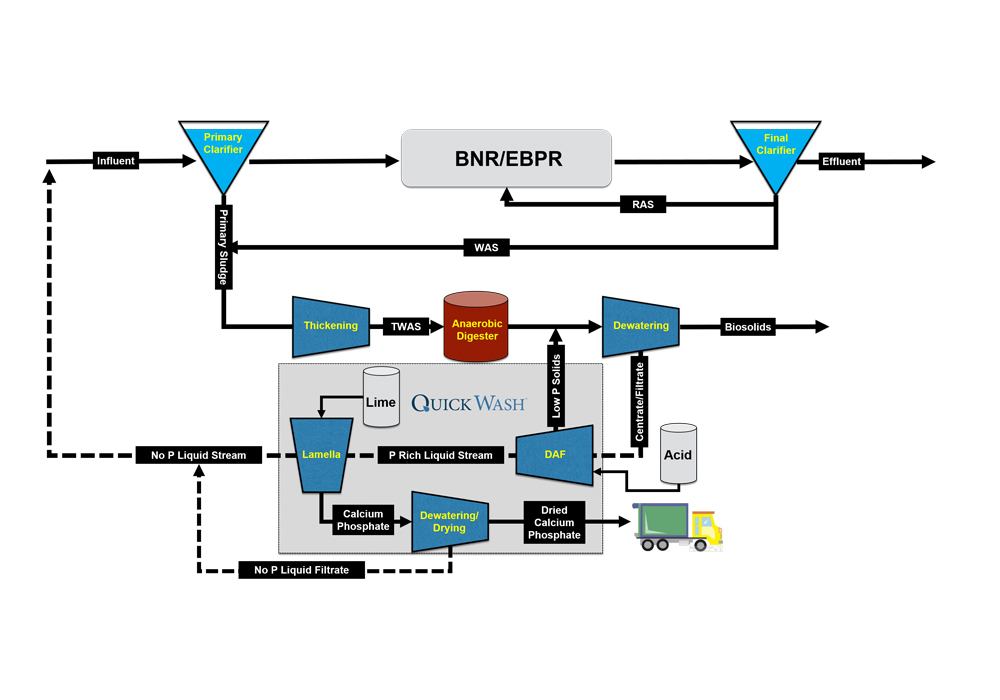

In the operation of the CAS process, the treated wastewater is separated from the biomass after having passed through the biological reactor basins. In the secondary clarifiers, the activated sludge solids separate via gravity and settle to the bottom while the treated water is discharged through the effluent launder. To maintain the process, a large portion of the sludge is returned to the biological reactor basins as return activated sludge (RAS). This maintains the proper food to mass (F/M) ratio and solids retention time (SRT) to assure proper biological performance. The remainder of the sludge is removed from the process as waste activated sludge (WAS) and is disposed of via digesting, dewatering and/or otherwise handled.